The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

A+A Smart Engineering Works

Lahore, Pakistan

E

11-50 Employees

-

Key takeaway

The company offers a wide range of machinery tailored to various industries, along with comprehensive maintenance programs and expert guidance to select the ideal machine design and model. Their services also include welding, assembling, and coating, ensuring complete project management for industrial needs.

Reference

Service

Custom Machinery – A+A Engineering

MachStruc. Private Limited.

Karachi Division, Pakistan

E

251-500 Employees

2020

Key takeaway

The company, MACHSTRUC, specializes in providing automated intra-logistic machines and structures, offering a comprehensive range of products and services tailored to warehousing needs. Their solutions include advanced industrial doors, automated and semi-automated shelving systems, and a variety of structures for energy generation, ensuring efficient and effective logistics operations.

Reference

Core business

About | MACHSTRUC

Crocyard Trading - Heavy Equipment

Sukkur, Pakistan

E

1-10 Employees

2018

Key takeaway

Crocyard Trading SMC-Pvt Ltd specializes in Heavy Lifting Equipment and Road Construction Machines, positioning itself as a key player in the industry. The company is actively seeking investors and manufacturers to expand its distribution network in Pakistan, particularly in relation to CPEC projects.

Reference

Core business

Supplying Heavy Lifting Equipment & Construction Machines

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

MACHINE YARD

Lahore, Pakistan

E

1-10 Employees

2006

Key takeaway

The company specializes in medium to large machine tools, offering a range of equipment including Deep Hole Boring Machines, Roll Grinding Machines, and Large Lathes.

Reference

Product

P1 | MACHINE YARD

The one & only source for used quality machinery & tools.

Maxen Engineering Group

Karachi Division, Pakistan

E

1-10 Employees

2010

Key takeaway

Maxen Engineering is a leading supplier of high-quality construction machinery in Pakistan, representing reputable international brands and offering a wide range of products for civil and mechanical engineering projects. Their commitment to promoting the latest tools and technologies ensures that clients have access to reliable construction equipment, which can be conveniently ordered online and delivered across the country.

Reference

Core business

suppliers of reliable and best quality construction machinery in Pakistan

Are you looking for suppliers of reliable and best quality construction machinery in Pakistan? We are the right choice for all your construction needs.

RECOPK

Lahore, Pakistan

E

51-100 Employees

-

Key takeaway

The company, Raheel Engineering Company (RECO), specializes in CNC machinery, offering high-quality systems for various applications, including milling and engraving. With extensive experience in CNC package preparation, they position themselves as a leading provider of CNC machines in Pakistan.

Reference

Core business

CNC Machining Tools We Provide Best Services for CNC Machines

CNC Machining Tools We Provide Best Services for CNC Machines RECO "Raheel Engineering Company" State of the art in CNC Market.

Rotary Mart (Sales Service & Spares of Rotating Equipment)

Karachi Division, Pakistan

E

11-50 Employees

2014

Key takeaway

ROTARY MART specializes in providing comprehensive engineering solutions, including installation, maintenance, and inspection services for both rotating and stationary machinery. The company emphasizes condition-based maintenance and project management across various engineering disciplines, ensuring reliable and efficient support for their clients' machinery needs.

Reference

Core business

ROTARY MART | An Engineering Solution Company

ALLIED ENGINEERING & SERVICES (PVT.) LIMITED

Karachi Division, Pakistan

E

251-500 Employees

1976

Key takeaway

Allied Engineering & Services (Pvt.) Ltd. specializes in Earthmoving Machinery and Power Generation Equipment in Pakistan, supported by a team of highly trained engineers available 24/7.

Reference

Product

SEM - Allied Engineering & Services (Pvt.) Ltd.

SEM Machinery

Commercial Zone

Karachi Division, Pakistan

E

51-100 Employees

2006

Key takeaway

The company offers a range of engineering solutions, including the supply and fabrication of machinery such as generators and conveyors. Their commitment to quality and customer satisfaction ensures timely and cost-effective services for various industrial needs.

Reference

Core business

Birds Services & Technologies

Brightsun Traders

Lahore, Pakistan

E

1-10 Employees

-

Key takeaway

Brightsun Traders specializes in a diverse range of sectors, including machinery rentals. They offer a variety of machinery and support services, ensuring quality and timely delivery across Pakistan.

Reference

Service

Services – Brightsun Traders

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

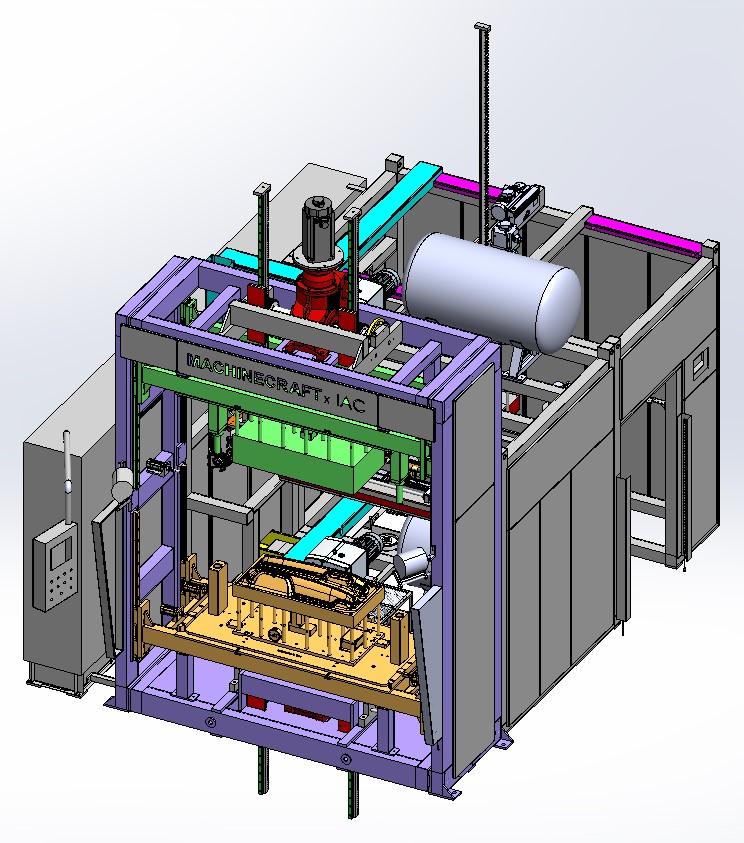

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

When exploring the machinery industry in Pakistan, several key considerations come into play. First, understanding local regulations and compliance standards is crucial, as these can significantly impact operational capabilities and market entry strategies. The industry faces challenges such as outdated technology and infrastructure, which can hinder productivity and competitiveness. However, there are also notable opportunities, particularly in sectors like agriculture, construction, and manufacturing, driven by urbanization and economic growth. Environmental concerns are increasingly relevant, as the industry must navigate regulations related to emissions and waste management. Companies that adopt sustainable practices may gain a competitive edge. The competitive landscape is diverse, with both local and international players vying for market share. Collaborating with local firms can provide insights into customer preferences and regulatory requirements. Furthermore, Pakistan's strategic location offers access to regional markets, making it a potential hub for machinery exports. Finally, staying informed about global market trends and technological advancements is essential, as these factors can influence local operations and strategic planning.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Pakistan |

| Amount of fitting manufacturers | 37 |

| Amount of suitable service providers | 33 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1976 |

| Youngest suiting company | 2020 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Automation, Manufacturing, Machinery Manufacturing, Electronics and Electrical engineering, Oil, Energy and Gas

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.