The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Cima

Bologna, Italy

B

101-250 Employees

1942

Key takeaway

CIMA specializes in the manufacture of gears and precision mechanical components, offering solutions for machinery and high-performance applications. Their proactive problem-solving approach and compliance with industry standards ensure quality and efficiency in their products.

Reference

Product

Solutions: Machinery | CIMA

Airworks SRL

Monfalcone, Italy

B

11-50 Employees

2007

Key takeaway

Airworks is an independent engineering consultancy that specializes in advanced systems, offering expertise in the design and development of machinery for various applications, including industrial machines and components for the steel industry. Their focus on lightweight and modular mechanical frames positions them as a key player in delivering innovative engineering solutions.

Reference

Product

INDUSTRIAL MACHINES AIRWORKS Engineering Advanced Systems. A contractor delivering efficient, highly reliable engineering and development capabilities to support advanced projects| Airworks

MEC-Europa Srl

Fontevivo, Italy

B

11-50 Employees

-

Key takeaway

Mec-Europa specializes in the engineering and production of parts for machinery used in various industrial sectors, ensuring quality and timely delivery through advanced in-house manufacturing processes. Their expertise and investment in research and development enable them to meet the diverse needs of clients, particularly in pharmaceuticals, packaging, and aerospace.

Reference

Product

MECHANICS AND VACUUM SYSTEMS FOR INDUSTRY - MEC EUROPA

Our advanced equipment includes 4 and 5 axle milling machines, CNC lathes, EDM and Wire EDM Machines as well TIG and MIG welding machines

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

OMC Roletto

Roletto, Italy

B

11-50 Employees

2000

Key takeaway

The company specializes in the production of mechanical components and machinery, utilizing advanced technologies and equipment to ensure high quality and flexibility in manufacturing. Their commitment to customer satisfaction and the ability to deliver tailored mechanical solutions positions them well in the competitive market.

Reference

Service

Special Equipment - Officine Meccaniche S.r.l.

O.M.C. produces mechanical equipment, following the specific needs and specifications of its clients.

MONTRADE SPA

Bologna, Italy

B

101-250 Employees

2004

Key takeaway

Montrade S.p.A. is a prominent machine manufacturer specializing in the cigarette tobacco industry, offering innovative machinery and technical assistance. Their commitment to redesigning a plastic-free future for filters highlights their focus on advanced manufacturing capabilities and support services.

Reference

Service

Machinery technical assistance, spare parts, production support

Montrade, GD and Hauni machine spare parts and service - remote assistance - maker technician - tobacco cigarette production support - preventive maintenance

AZIONARIA COSTRUZIONI MACCHINE AUTOMATICHE A.C.M.A. SPA

Bologna, Italy

B

101-250 Employees

1924

Key takeaway

ACMA is a leading manufacturer of automatic packaging machines, particularly for sectors like confectionery, detergents, and tea. With nearly 100 years of experience, ACMA emphasizes innovation and quality in its machinery, making it a key player in the packaging solutions market.

Reference

Product

Machines & Products | ACMA

SMART MACHINERY

Tortona, Italy

B

11-50 Employees

2002

Key takeaway

National Machinery specializes in designing and manufacturing high-speed, high-precision machinery for the production of metal fasteners and parts. Their commitment to customer service and support enhances the value of their advanced equipment offerings.

Reference

Service

Service | SMART Machinery | Italy

We offer technical support, spare parts, field and remote service. We are decidated to quality customer support and maintain support centers around the world.

MANITECH Srl

Su Masu/Elmas, Italy

B

1-10 Employees

2016

Key takeaway

Manitech specializes in the sale of lifting equipment and has a strong partnership with Grove, offering both on-road and off-road solutions. They are also a dealer for Multitel and JLG aerial platforms and partner with Yanmar for earth-moving machinery.

Reference

Core business

Manitech | Vendita e assistenza per le macchine da lavoro

Alta professionalità e know-how tecnico di livello rendono Manitech un’azienda reattiva e versatile rispetto alle esigenze del mercato moderno.

La Meccanica

Cittadella, Italy

B

11-50 Employees

1961

Key takeaway

La Meccanica specializes in the production of machinery for the animal feed, biomass, recycling, and fertilizing industries, emphasizing quality and innovation. Their precision-manufactured spare parts and efficient after-sale service ensure optimal performance and longevity of their equipment.

Reference

Core business

Company - La Meccanica

VEMAUT

Burago di Molgora, Italy

B

1-10 Employees

-

Key takeaway

La VEMAUT MACCHINE SRL specializes in the commercialization of new and used machinery, particularly focusing on highly efficient and cost-effective machine tools. With over thirty years of experience, the company offers strong financial support for machinery purchases and exclusive distribution of renowned brands, ensuring optimal investment opportunities for customers.

Reference

Core business

Homepage - Vemaut Macchine Srl

Brand in escusiva Siamo distributori e in alcuni casi esclusivisti di alcuni dei più importanti brand di macchine utensili al mondo. Esclusiva di distribuzione e assistenza nelle province occidentali della Lombardia per il marchio coreano Hwacheon Primaria azienda Coreana specializzata nella costruzione di macchine utensili da oltre 70 anni. Sicuramente il miglior brand per rapporto […]

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

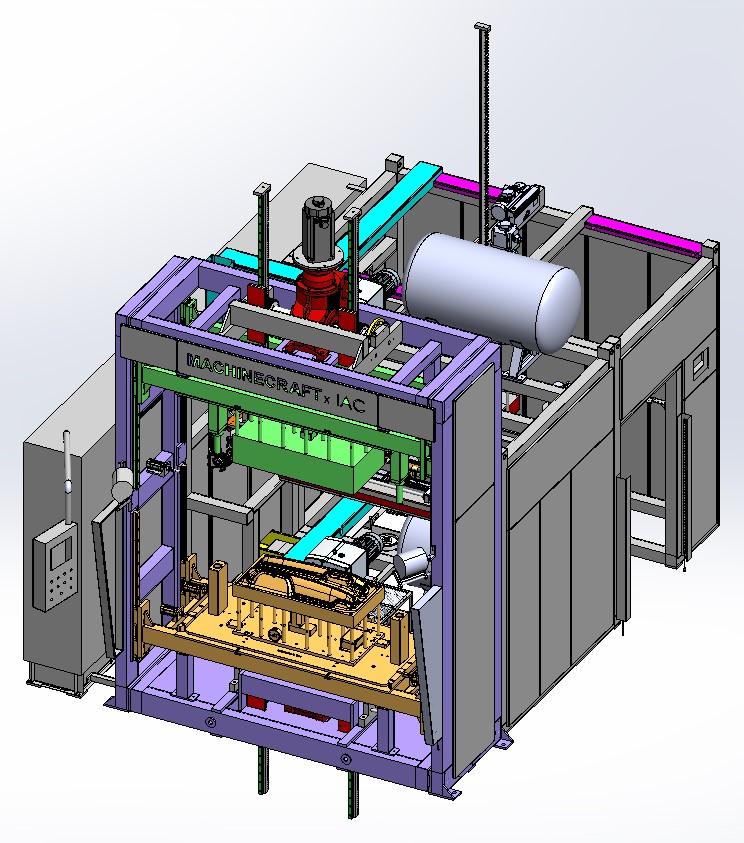

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

In the Machinery industry in Italy, several key considerations are essential for thorough research. Italy is known for its strong manufacturing base and innovation, particularly in sectors like automotive, textiles, and food processing machinery. It's important to understand the regulatory landscape, which includes compliance with EU standards, safety directives, and environmental regulations that impact production processes. Challenges in this market often stem from global competition, particularly from low-cost manufacturers in Asia, and ongoing supply chain disruptions. However, opportunities exist due to Italy's reputation for high-quality machinery and engineering expertise, which can attract international clients looking for specialized solutions. Environmental concerns are increasingly significant, as sustainable practices and energy efficiency become more critical in manufacturing processes. The competitive landscape is characterized by a mix of established companies and emerging startups, creating a dynamic environment for innovation. Additionally, understanding the global market relevance is crucial, as Italy's machinery exports are vital to its economy, with significant demand from both European and non-European markets. Being aware of these factors can provide valuable insights for anyone interested in navigating the machinery industry in Italy effectively.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Italy |

| Amount of fitting manufacturers | 310 |

| Amount of suitable service providers | 231 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1924 |

| Youngest suiting company | 2016 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Machinery Manufacturing, Other, Manufacturing, Automation, IT, Software and Services

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.