The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

EURO MACHINES INTERNATIONAL SP Z O O

Luboń, Poland

B

1-10 Employees

2015

Key takeaway

Euro-Machines is a key supplier of winery equipment, highlighting its strong partnership with Scharfenberger Maschinenbau, which enhances its service and parts availability. With a commitment to customer satisfaction and locations on both coasts, Euro-Machines ensures comprehensive support for its machinery offerings.

Reference

Product

AS10_02-1 - Euro-Machines

BMG Trade Food Processing Machinery

Komarów-Osada, Poland

B

1-10 Employees

-

Key takeaway

The company specializes in buying and selling new and used food processing machinery from renowned manufacturers, ensuring they meet the high standards and requirements of their customers across various fields. Their commitment to understanding the food industry's needs allows them to provide equipment that aligns with market demands, making them a reliable source for both single machines and complete processing lines.

Reference

Core business

Food Processing Machinery - BMGTrade

Tincors.com

Poland

B

11-50 Employees

2019

Key takeaway

Tincors is a global company specializing in machinery relocation services, offering a skilled team with extensive experience in the precise planning, secure transportation, and professional installation of industrial equipment. Their commitment to quality and timely execution makes them a reliable partner for all machinery-related needs.

Reference

Core business

Tincors - global machinery relocation

Tincors.com provide services in the industrial machine sector. They mainly focus on machinery relocation, team leasing and technician recruitment.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

MACHINE TOOLS INTERNATIONAL SP Z O O

Rybnik, Poland

B

11-50 Employees

2002

Key takeaway

Machine Tools International is a key supplier of CNC machine tools and industrial automation solutions, representing leading manufacturers like HYUNDAI WIA and HANWHA PRECISION MACHINERY. With extensive experience and a commitment to quality, they provide comprehensive support and reliable machining technology for the manufacturing sector.

Reference

Core business

Sprzedaż maszyn przemysłowych - Machine Tools International, Rybnik

Metal Team Sp. z o.o. Sp. K.

Wanaty, Poland

B

51-100 Employees

1996

Key takeaway

Metal Team offers comprehensive CNC machinery service, including repairs and maintenance, ensuring the reliable operation of equipment. Their extensive experience and technical expertise contribute to high-quality support for CNC machinery.

Reference

Service

Metal Team - CNC MACHINERY SERVICE - CNC machine tool repairs & service

Mine Master

Złotoryja, Poland

B

251-500 Employees

1993

Key takeaway

The company specializes in manufacturing drilling and bolting rigs, offering a comprehensive range of machines essential for mining and tunneling operations. They emphasize close collaboration with customers to deliver customized mining machinery tailored to specific working conditions, reflecting their commitment to quality and expertise in the field.

Reference

Core business

Underground mining equipment manufacturers - Mining machines, machinery - Mine Master LTD

Mechanica CNC

Bielsko-Biała, Poland

B

11-50 Employees

2009

Key takeaway

The company's machine park is equipped with advanced DMG MORI machines, highlighting its commitment to high-quality production and continuous employee training in machine engineering and machining.

Reference

Core business

MechanicaCNC - Mechanica CNC

Nasz park maszynowy wyposażony jest w jedne z najbardziej zaawansowanych technologicznie maszyn marki DMG MORI. Prowadzimy stałą współpracę z firmą DMG MORI w

Airmech

Poland

B

1-10 Employees

-

Key takeaway

Airmech specializes in providing professional consultations for the selection of equipment and systems for ships and boats, highlighting their extensive experience and commitment to the maritime market. With a diverse range of products across various departments, including mechanics, Airmech ensures access to high-quality machinery and systems.

Reference

Product

Mechanics – Airmech – Marine Equipment

KDT EUROPE Sp.z o.o.

Warsaw, Poland

B

1-10 Employees

2017

Key takeaway

KDT Woodworking Machinery specializes in manufacturing high-quality machinery for furniture production, with a focus on panel machinery across four key divisions: Edging, Cutting, Drilling, and Automatic Line. Their products are distributed in over 70 countries, highlighting their global reach and commitment to quality and affordability.

Reference

Product

Boring Machines

KATANA Machinery

Trzebnica, Poland

B

1-10 Employees

-

Key takeaway

The company collaborates with suppliers from Europe, the Middle East, and Asia to offer a wide range of high-quality attachments specifically designed for compact tractors. With a focus on innovation and customer feedback, they continually expand their portfolio, including their own production of solid front loaders for Japanese mini tractors.

Reference

Product

Spare parts Archives - Katana Machinery

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

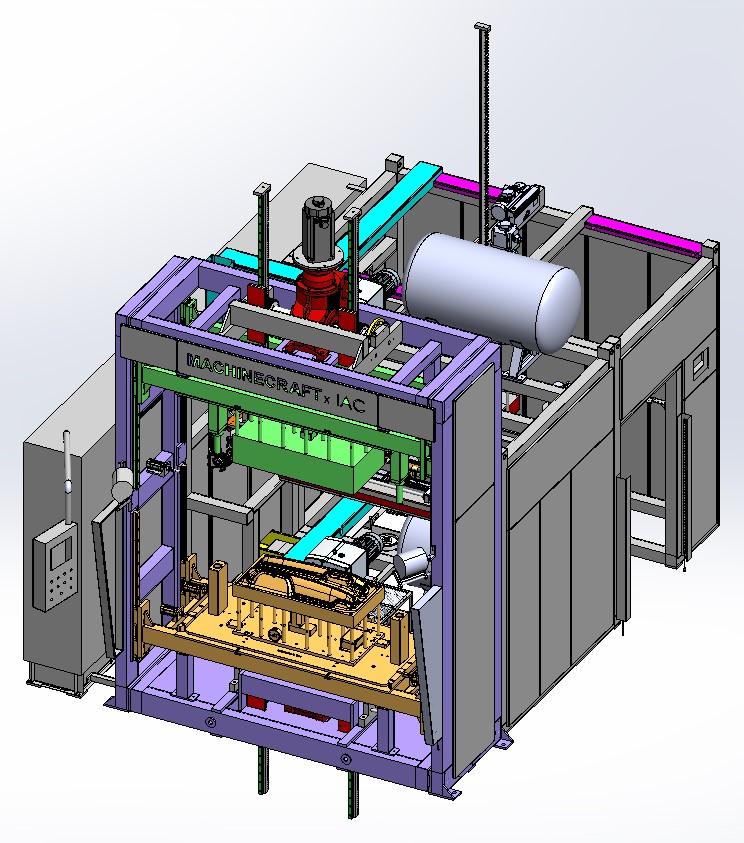

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

When exploring the Machinery industry in Poland, several key considerations emerge. Firstly, Poland's strategic location in Central Europe offers access to major markets, which enhances logistics and trade opportunities. The industry benefits from a skilled workforce, particularly in engineering and manufacturing, which is crucial for innovation and production efficiency. However, potential investors should be aware of the regulatory environment, including compliance with EU standards and local laws that govern manufacturing processes, safety, and environmental impact. Challenges such as competition from established European machinery manufacturers and the need for modernization in some sectors may pose risks. Nonetheless, there are significant opportunities for growth, especially in automation and Industry 4.0 technologies. The Polish government also supports investments in green technologies and sustainable practices, responding to global environmental concerns. Furthermore, the competitive landscape is evolving, with both domestic and international players vying for market share. Understanding market trends, such as the increasing demand for advanced machinery and the shift towards sustainable production, is crucial for making informed decisions. Overall, thorough research into these factors will provide valuable insights for anyone interested in entering the Polish Machinery industry.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | Poland |

| Amount of fitting manufacturers | 37 |

| Amount of suitable service providers | 35 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1993 |

| Youngest suiting company | 2019 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Manufacturing, Other, Machinery Manufacturing, Automation, IT, Software and Services

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.