The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Machinery

Dartford, United Kingdom

A

- Employees

-

Key takeaway

Machinery is a monthly magazine that targets production engineers and managers, focusing on technological innovations and developments in manufacturing technology, particularly in areas like machine tools and tooling. It serves as a key resource for professionals engaged in metalcutting and metalforming.

Reference

Core business

Machinery - About Us

Buy Machinery

Horsham, United Kingdom

A

1-10 Employees

-

Key takeaway

Buy Machinery is the UK's leading marketplace for construction machinery, offering a platform to buy and sell the latest plant machinery.

Reference

Core business

Buy Machinery

Maquina Intelligent Networks Ltd

Harrogate, United Kingdom

A

1-10 Employees

-

Key takeaway

Maquina leverages its experience with leading IT providers to offer innovative solutions for managing large-scale data, ensuring a data-driven approach that enhances operational performance. As a Microsoft partner, Maquina is well-equipped to guide businesses in optimizing their data placement and utilizing advanced technologies.

Reference

Service

Services | Maquina

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Omnia Machinery

United Kingdom

A

11-50 Employees

2017

Key takeaway

Omnia Machinery is a global trader specializing in used construction equipment, offering a wide range of high-quality machinery from various sectors, including quarrying, road construction, earth moving, and cranes. Their stringent quality checks and comprehensive customer service ensure that clients receive reliable and safe machinery.

Reference

Core business

Home

Omnia Machinery are providers of construction and plant machinery from across the globe, we source the best quality used machinery from quarry, road construction, earth moving and cranes.

The Saw Centre Ltd

Glasgow, United Kingdom

A

51-100 Employees

1973

Key takeaway

The company operates a state-of-the-art Vollmer CNC factory in Glasgow, specializing in the service and sharpening of saw blades and the manufacturing of solid carbide tools, highlighting their expertise in advanced machinery.

Reference

Product

Machinery - Products

SW Hire

Chippenham, United Kingdom

A

11-50 Employees

2003

Key takeaway

SW Machinery Hire specializes in providing a wide range of modern agricultural equipment and plant machinery for hire, catering to the ever-changing needs of the industry. With over 20 years of experience, the company is a trusted provider, offering both long and short-term rental options.

Reference

Core business

Modern agricultural equipment and plant machinery hire

SW Machinery Hire - specialising in Agricultural and Plant machinery hire nationwide, on a long or short term basis.

World Machinery Ltd

Bridgnorth, United Kingdom

A

251-500 Employees

-

Key takeaway

World Machinery Ltd is a leading supplier of sheet metal working machinery, specializing in high-quality machines for bending, cutting, rolling, and forming. Their expertise and experience ensure comprehensive support for all your machinery needs, particularly in laser cutting.

Reference

Core business

World Machinery | New & Used Sheet Metal Machines

World Machinery is a leading supplier of sheet metal working machinery. We offer a wide range of high-quality machines for bending, cutting, rolling, and forming sheet metal.

Project Machinery

South Oxfordshire, United Kingdom

A

1-10 Employees

-

Key takeaway

Project Machinery is a UK-based business that specializes in buying and selling quality used machine tools, including lathes, mills, and various workshop machinery. They have a strong network for sourcing and placing machinery, ensuring a fair and accurate description of their stock since their establishment in 1990.

Reference

Core business

Welcome to Project Machinery

Machinery & Manufacturing

London, United Kingdom

A

1-10 Employees

2021

Key takeaway

The text highlights the company's focus on machinery and manufacturing, particularly mentioning manual machine tools. Additionally, it notes the transformative impact of Meltio's additive manufacturing technology on metal part production.

Reference

Product

Manual Machine Tools - Machinery & Manufacturing

Machinery World

Hinckley and Bosworth, United Kingdom

A

11-50 Employees

1999

Key takeaway

Machinery World specializes in providing the dairy and food industry with high-quality, competitively priced secondhand machinery. With a global reach and expertise in sourcing, they ensure access to top-notch dairy processing equipment.

Reference

Core business

About us - Machinery World

Who’s behind Machinery World?

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

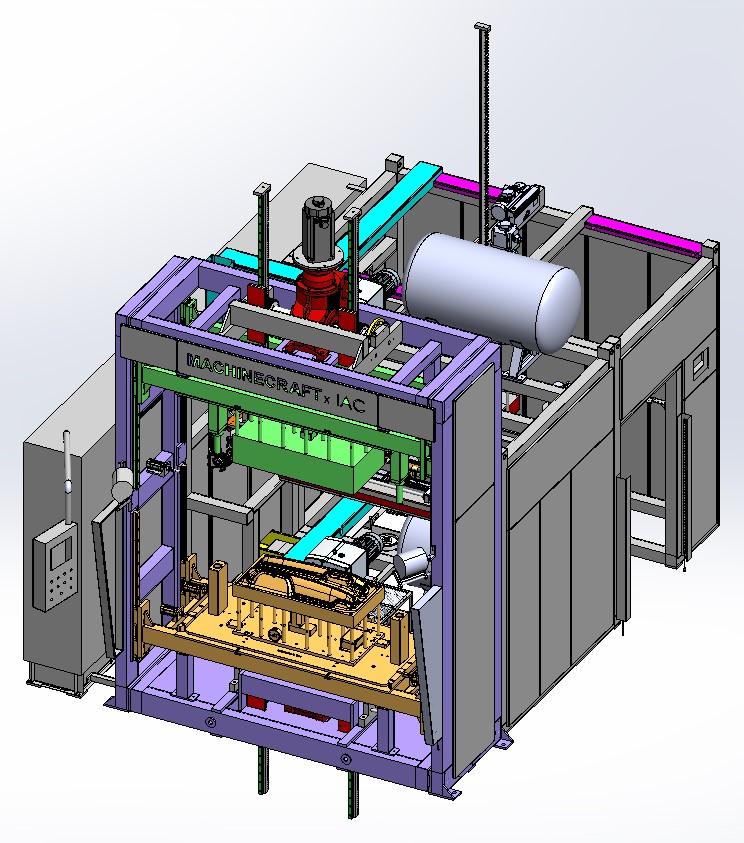

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

When exploring the machinery industry in the United Kingdom, several key considerations are essential for effective research. Understanding the regulatory landscape is crucial, as adherence to health, safety, and environmental standards is mandatory. The UK’s commitment to sustainability drives innovation in machinery, emphasizing energy efficiency and reduced emissions. Challenges such as supply chain disruptions and labor shortages have become prominent, particularly in the wake of recent global events, affecting production timelines and costs. Opportunities abound in sectors like renewable energy, automation, and advanced manufacturing technologies, which are experiencing growth and demand for innovative solutions. The competitive landscape is characterized by a mix of established players and emerging startups, each vying for market share through technological advancements. Additionally, the UK's machinery sector is increasingly relevant on the global stage, as British companies often export high-quality machinery and expertise, benefiting from strong international relationships. Prospective investors or partners should consider the implications of Brexit, which has reshaped trade relationships and regulatory frameworks, potentially impacting market access and labor availability. Overall, thorough research into these factors will provide valuable insights for anyone interested in navigating the UK machinery industry effectively.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | United Kingdom |

| Amount of fitting manufacturers | 1842 |

| Amount of suitable service providers | 2457 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1973 |

| Youngest suiting company | 2021 |

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Who are Start-Ups in the field of Machinery?

Start-Ups who are working in Machinery are Machinery & Manufacturing

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Machinery Manufacturing, Manufacturing, Other, Construction, IT, Software and Services

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.