The B2B platform for the best purchasing descision. Identify and compare relevant B2B manufacturers, suppliers and retailers

Close

Filter

Result configuration

Continents

Select continent

Locations

Result types

Company type

Select company type

Industries

Select industry

Company status

Select company status preset

Number of employees

Min.

Max.

Founding year

Platteau Subcontracting

Poperinge, Belgium

A

11-50 Employees

1953

Key takeaway

Platteau specializes in the production of exclusive parts for various applications, highlighting their modern and comprehensive machinery that enables precision work. With over 50 years of experience, the company focuses on manufacturing unique and complex parts, making it a key supplier for machine building and construction across different sectors.

Reference

Service

Services

Price Machinery

Hawthorne, United States

B

1-10 Employees

2019

Key takeaway

The company has established a nationwide network of machine providers, allowing users to receive competitive pricing from multiple options for their machinery needs. This service connects customers directly with providers, ensuring access to a wide variety of equipment, including essential forklifts for industrial applications.

Reference

Core business

About Machine Providers

After years of struggling to find quality equipment providers, Machine Providers was born. The rest is history but equipment rental will never be the same.

Machinery Masters Inc.

Hamilton, Canada

A

11-50 Employees

2008

Key takeaway

Machinery Masters Inc. is dedicated to providing top-quality industrial machinery solutions, offering same or next day service and expertise in a wide range of machine makes and models. With a team of eight in-house technicians, they are well-equipped to address any machinery-related issues.

Reference

Core business

Machinery Masters Inc. - CNC Machine Sales, CNC Machine Service

We are dedicated to delivering top-quality industrial machinery solutions through collaborations with leading manufacturers.

Looking for more accurate results?

Find the right companies for free by entering your custom query!

25M+ companies

250M+ products

Free to use

Machinery Marketing Solutions

Barcelona, Spain

A

1-10 Employees

2016

Key takeaway

Machinery is a high-performance advertising unit driven by creativity, emphasizing its belief that marketing must meet customer needs.

Reference

Service

service – Machinery

Machinery

Dartford, United Kingdom

A

- Employees

-

Key takeaway

Machinery is a monthly magazine that targets production engineers and managers, focusing on technological innovations and developments in manufacturing technology, particularly in areas like machine tools and tooling. It serves as a key resource for professionals engaged in metalcutting and metalforming.

Reference

Core business

Machinery - About Us

MachineryAgency

Kaunas, Lithuania

A

11-50 Employees

2013

Key takeaway

The company specializes in the sales and service of used manufacturing machinery, offering support throughout the entire equipment lifecycle, from selection to installation and ongoing service. Their mission is to create profitable opportunities in the used machinery market, addressing challenges that often hinder sales dynamics.

Reference

Core business

About Us | MachineryAgency

We are here for you as a “single point” sales & service source assisting throughout the whole production equipment lifecycle: machinery selection, installation & continuous service. Established in 2013 and now unite network of agents around the Wo...

Marcus Machinery

Richland Township, United States

B

1-10 Employees

2012

Key takeaway

Marcus Machinery is a key distributor of machine tools in the mid-Atlantic region, offering a premier line of machine tool manufacturers and automation specialists. Their team provides customized solutions and fosters strong customer relationships, highlighting their expertise in world-class machine tool technology.

Reference

Core business

Marcus Machinery

Bringing World Class Machine Tool Technology to Western Pennsylvania.

Access Machinery

Vaughan, Canada

A

11-50 Employees

2016

Key takeaway

Access Machinery is a key distributor of metal fabricating equipment in Canada, offering a comprehensive range of machinery including Fiber Laser systems, Press Brakes, and Plate Rolls. Their commitment to innovation and turnkey solutions makes them a valuable partner for manufacturing companies seeking advanced metal fabrication technologies.

Reference

Core business

Metal Fabricating Solutions | Access Machinery Canada

Access Machinery offers turnkey solutions for manufacturing companies in Canada. We provide machinery installation, software training, ERP integration, and more.

Midwest Machine Tool Supply

Minneapolis, United States

B

11-50 Employees

1948

Key takeaway

Midwest Machine Tool Supply offers a diverse range of machinery products and services through partnerships with over 80 vendors, emphasizing their commitment to customer satisfaction.

Reference

Product

Machinery - Products

Master Machine

Woodbury, United States

B

11-50 Employees

-

Key takeaway

The company specializes in precision parts machining, serving industries like defense, aerospace, and automotive, where high-quality components are crucial for performance. Their commitment to innovative solutions and 100-percent quality ensures they meet the complex machining challenges of trusted brands.

Reference

Core business

Machinery - Master Machine

Technologies which have been searched by others and may be interesting for you:

A selection of suitable products and services provided by verified companies according to your search.

Service

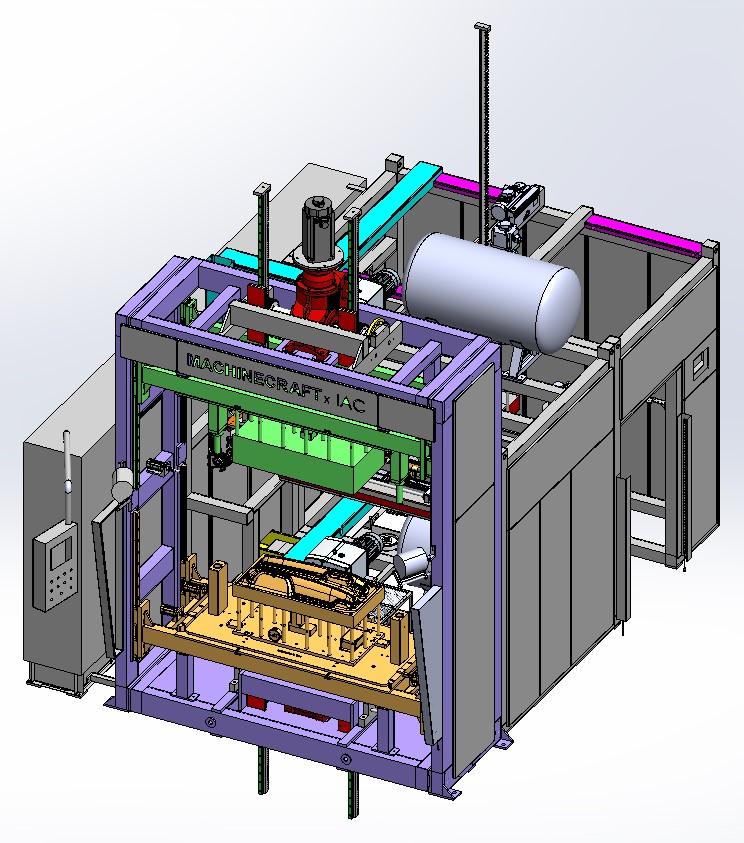

IMG Thermoforming Machine

Go to product

A selection of suitable use cases for products or services provided by verified companies according to your search.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Use case

Instrument Panel for E-Mobility

Automotive, E-Mobility

### Summary of Lightweight Material for Instrument Panels (IP) & Door Panels (DP) Compared to Slush Molding The material from Tatsuta Chemical is used for **instrument panels (IP) and door panels (DP)** in automobiles, providing **lightweight, high-quality surface finishes**. Here’s how it compares to **slush molding**: #### **1. Thermoforming vs. Slush Molding** - **Thermoforming Process (Used with Tatsuta Material)**: - Uses a **pre-formed sheet** heated and vacuum-formed over a mold. - Less material wastage. - Can integrate **reinforcements** like back-foaming to add structure without extra weight. - **Consistent thickness** leading to more predictable mechanical properties. - **Slush Molding**: - Uses **PVC powder**, which is poured into a mold, heated, and then excess material is removed. - Results in **thicker** and **heavier parts** due to the nature of the material build-up. - Involves **higher material waste**. #### **2. Weight Reduction** - Tatsuta’s material is **lighter** because: - Uses **TPO-based skin** instead of **PVC** (PVC is denser). - Can be reinforced with **lightweight foams** or substrates. - Thermoformed parts **require less resin**, unlike slush-molded parts which accumulate extra material. - **Example of Weight Difference**: - **Slush-molded IP**: ~4.5–5 kg per set. - **Thermoformed IP with lightweight reinforcement**: ~3.2–3.8 kg per set. - **Savings of 20-30% in weight**, leading to better fuel efficiency. #### **3. Cost & Process Efficiency** - **Lower Material Cost**: Thermoforming allows the use of **co-extruded sheets**, reducing material consumption. - **Lower Cycle Time**: **Thermoforming process cycle time ~90-120 sec**, compared to **slush molding (~180 sec or more)**. - **No Need for Secondary Processing**: Slush molding often requires **post-processing steps like trimming and edge folding**, whereas **thermoforming integrates these into the process**. #### **4. Aesthetic & Durability Advantages** - Tatsuta’s **TPO-based sheets**: - **Better UV resistance** (less yellowing over time). - **Softer touch feel** without the weight of thick PVC layers. - **Easier to texture** compared to slush-molded PVC skins. #### **5. Market Adoption in India** - **Thermoforming + Press Lamination** is becoming popular in **premium vehicles** due to: - Weight savings leading to **higher fuel efficiency**. - **Sustainability concerns** (TPO-based vs. PVC-based skins). - Growing adoption by **OEMs like Suzuki, Tata, Hyundai**. ### **Conclusion** Thermoformed surfaces using Tatsuta’s materials offer **significant weight savings (~30%)**, faster cycle times, and **improved material efficiency** compared to slush molding. This makes them ideal for **cost-effective, high-quality automotive interior production**.

Machinery refers to machines and their components used for various industrial, agricultural, and construction applications. These devices are designed to perform specific tasks, often improving efficiency and productivity in operations. Machinery can range from simple tools to complex systems, including engines, pumps, conveyor systems, and heavy equipment like excavators and bulldozers. In many sectors, machinery plays a vital role in automation, allowing for precision and speed that manual labor cannot achieve. The advancement of technology has led to the development of more sophisticated machinery, integrating features such as robotics, artificial intelligence, and IoT capabilities to enhance performance and data collection.

Machinery plays a crucial role in industrial applications by automating processes and enhancing productivity. It operates through various mechanisms designed for specific tasks, such as cutting, shaping, or assembling materials. The integration of advanced technologies like robotics, sensors, and computer controls allows machinery to perform complex operations with precision and efficiency. In industrial settings, machinery can be categorized into several types, including CNC machines, conveyors, and hydraulic systems. These machines work together in production lines to streamline workflows, reduce manual labor, and ensure consistent quality in products. By leveraging machinery, industries can achieve higher output rates, minimize errors, and ultimately lower operational costs.

1. Increased Efficiency

Advanced machinery is designed to operate with higher efficiency, reducing the time and energy required for production processes. This leads to increased output and lower operational costs.

2. Enhanced Precision

Utilizing cutting-edge technology allows for greater precision in manufacturing, resulting in higher quality products. This minimizes waste and rework, which can significantly improve profitability.

3. Improved Safety

Modern machinery often incorporates advanced safety features that protect operators and reduce the risk of accidents. This contributes to a safer work environment and can lower insurance costs.

4. Flexibility and Adaptability

Advanced machinery can often be programmed for various tasks, allowing businesses to adapt quickly to changing market demands. This flexibility ensures that manufacturers can meet diverse customer needs without significant downtime.

5. Data-Driven Insights

Many advanced machines come equipped with IoT capabilities, providing valuable data analytics. This information helps in monitoring performance, predicting maintenance needs, and optimizing production processes.

1. CNC Machines

CNC (Computer Numerical Control) machines are crucial for precision manufacturing. They automate the control of machining tools, allowing for intricate designs and consistent production quality.

2. Injection Molding Machines

These machines are essential for producing plastic parts by injecting molten plastic into molds. They are widely used in various industries to create items ranging from consumer goods to automotive components.

3. Lathes

Lathes are fundamental for shaping materials by rotating them against a cutting tool. They are versatile and can be used to produce cylindrical components in many manufacturing processes.

4. Milling Machines

These machines are vital for removing material from a workpiece using rotary cutters. They allow for complex shapes and precise dimensions, making them indispensable in manufacturing.

5. Presses

Mechanical and hydraulic presses are used to shape materials through deformation. They are essential for tasks like stamping, forging, and forming metal parts in various sectors.

Machinery plays a critical role in enhancing production efficiency across various industries. By automating repetitive tasks, machinery reduces the time required for production processes, allowing for quicker turnaround times. This automation minimizes human error, leading to consistent product quality and fewer defects, which in turn reduces waste and costs. Additionally, advanced machinery often includes features such as real-time monitoring and data analytics. These capabilities enable operators to identify bottlenecks and optimize workflows, further increasing overall operational efficiency. As a result, businesses can maximize output while minimizing resource consumption.

Some interesting numbers and facts about your company results for Machinery

| Country with most fitting companies | United States |

| Amount of fitting manufacturers | 9169 |

| Amount of suitable service providers | 10000 |

| Average amount of employees | 11-50 |

| Oldest suiting company | 1948 |

| Youngest suiting company | 2019 |

20%

40%

60%

80%

Some interesting questions that has been asked about the results you have just received for Machinery

What are related technologies to Machinery?

Based on our calculations related technologies to Machinery are Big Data, E-Health, Retail Tech, Artificial Intelligence & Machine Learning, E-Commerce

Which industries are mostly working on Machinery?

The most represented industries which are working in Machinery are Machinery Manufacturing, Other, Manufacturing, Automation, Construction

How does ensun find these Machinery Suppliers?

ensun uses an advanced search and ranking system capable of sifting through millions of companies and hundreds of millions of products and services to identify suitable matches. This is achieved by leveraging cutting-edge technologies, including Artificial Intelligence.